| Price: | 15,750৳ |

| Status : | In Stock |

| Product Code: | 2416 |

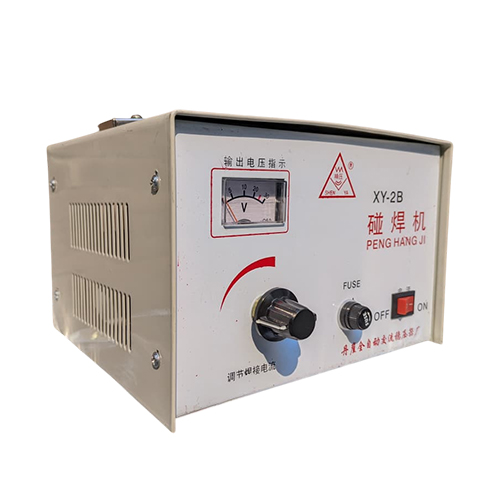

| Brand: | Shen Ya |

The butt welding machine is an ideal tool for replacing a soldering iron in the motor manufacturing and motor maintenance industries.

It features fast welding speed, excellent welding quality, and no need to scrape the enamel insulation when welding enameled wires.

▸ OPERATING METHODS

1. Connect the two wires equipped with long-nose pliers and carbon brushes to the binding posts at the back of the butt welding machine, respectively.

2 . Scrape off the enamel insulation at the connection points of the two wires to be welded. Second, clamp the connection points of the two wires with long-nose pliers to ensure electrical conduction. Third, adjust the current to an appropriate level (the thicker the wires, the higher the current required). Then, cut the two wires to be welded flush. Next, touch the end of the butt welding machine equipped with carbon brushes against the two wires to generate an electric arc, allowing the two wires to fusion-weld together. When the wire ends form a spherical shape, the butt welding is successful.